Fu Chun Shin (FCS) Will Be Awaiting Your Visit At The 2023 Taichung Plastics And Rubber Industry Show

The upcoming Taichung Plastics and Rubber Industry Show, scheduled from July 13 to July 17, 2023, at the Taichung International Exhibition Center, is a 5-day event. With a total of 200 booths, the exhibition will showcase the latest advancements in plastic molding equipment for the year 2023. One prominent participant in the event is the Fu Chun Shin (FCS) Group, a renowned company in the global plastic rubber injection molding equipment industry. FCS Group will be unveiling their new models, including the "All-electric Multi-component" CT-R series, the "Advanced Servo Hydraulic" SA series, and the "iMF4.0 Intelligent Manu Factory Mucell." These models exemplify FCS's expertise in integrating research and development technology with manufacturing processes, helping their customers excel in the highly competitive market. At the FCS booth, visitors can expect to find solutions tailored to various industries such as medical products, household items, food packaging, and automotive parts.

In light of the prevailing environmental and energy landscape, both local governments and businesses have made significant strides by declaring their net-zero targets and outlining plans for carbon reduction. Additionally, renowned international brands have taken the lead in announcing their own plans for achieving net-zero carbon emissions (carbon neutrality). These initiatives have also influenced major manufacturing plants to embrace the concept of "net-zero carbon emissions" through the implementation of the "Clean Energy Supply Chain Program." Previously, the adoption of an "energy-saving strategy" was considered merely an "option for survival" among injection molding plants. However, with the emergence of global carbon neutrality laws and trade regulations, it has now become a "necessary condition for survival".

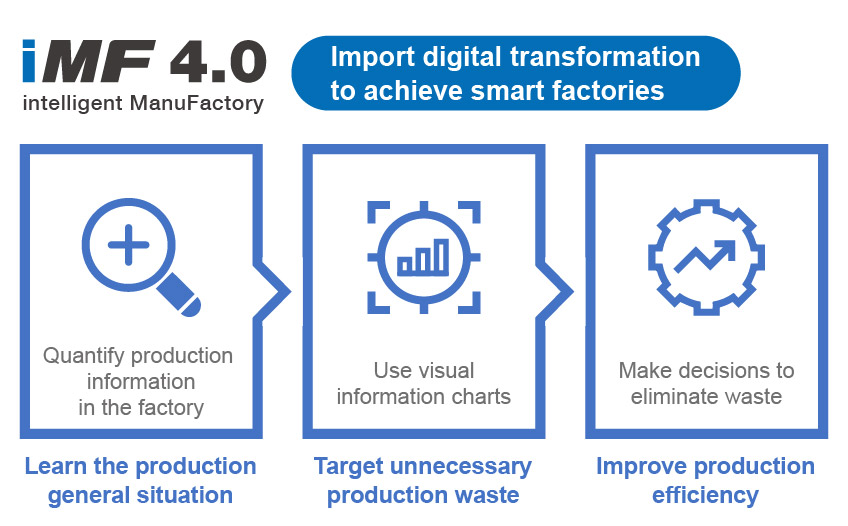

As stated by CEO Alan Wang, in the era of Industry 4.0, FCS's independently developed "iMF4.0 Intelligent Manu Factory Mucell" stands as an invaluable asset for its customers’ journey towards smart transformation. This innovative solution can be seamlessly integrated into injection molding machines from various brands, enabling them to connect with surrounding information and autonomously adjust and control quality parameters. By employing this system, a smart sensor module can be implemented, leading to improved product yield, reduced production waste, and proactive warnings through engineering monitoring and feedback functions, thereby mitigating losses caused by unexpected downtime. At the Taichung Plastics and Rubber Industry Show, FCS will showcase their expertise in "Smart Manufacturing" production management. This demonstration aims to assist business owners in exploring superior strategies and methodologies within the traditional injection molding industry. Focusing on equipment, process technology, and production management, the goal is to navigate the challenges posed by the rapid global trend towards carbon neutrality. FCS is dedicated to helping businesses proactively respond to the demands of carbon neutrality in the future.

》》Customer performance case: Dilemma facing plastic injection industry and solutions

Two-component Packaging Container Molding System: CT-230R

The CT-R series introduces a cutting-edge combination of FCS's two key strengths: "all-electric" and "two-component" technologies. The CT-R series Rotary Table All-electric Two-component Injection Molding Machine is specifically designed for high-precision and high-cleanliness multi-color molding applications. Equipped with a precise injection unit featuring two or multiple independent material tube groups, this machine enables simultaneous injection, resulting in significantly reduced molding cycles. The all-electric turntable offers fast and stable rotation, with a speed increase of 30%-50% and an impressive accuracy of 0.005°. These advancements ensure that the injection-molded products achieve enhanced precision and stability. The CT-R series also boasts a new 21.5-inch touch screen interface, providing an intuitive and convenient operating experience.

FCS has consistently achieved record-breaking sales of its two-component injection molding machines, surpassing USD 93 million in 2022. These machines come in five different types and offer 24 configurable options for injection units, providing comprehensive coverage for mold designs across various industries and enabling multi-station customization for production lines. In the upcoming Taichung Plastics and Rubber Industry Show, FCS will showcase an all-electric, two-component machine with a clamping force of 230 tons. This machine will demonstrate the production of a two-component and two-material sealed preservation box, where both the box and cover are molded simultaneously. By using food-grade PP and TPE elastomer, the machine eliminates the need for manual filling of silica gel strips in the second process, resulting in significant savings in labor costs. Additionally, the molding cycle time is reduced to just 30 seconds.

New-generation Intelligent Molding System: SA-160

Introducing FCS's enhanced SA series, an optimized outward toggle injection molding machine that raises the bar in terms of specifications and design. Retaining a harmonious blend of aesthetics and human factors engineering, this machine embodies both style and functionality. The SA series leverages the advantages of an advanced electronic control system, offering superior performance. It incorporates a servo ejection full closed circuit, ensuring remarkable ejection time stability of over 99.9%. As a result, the weight of the molded product remains consistent, delivering reliable and predictable outcomes. The mold locking force is intelligently distributed to the center of the mold, guaranteeing uniform force application and minimizing the likelihood of defective products. This optimization contributes to improved product yield and reduced instances of abnormalities. Additionally, the SA series boasts a 23% reduction in mold length, effectively reducing the machine's footprint and optimizing plant space utilization. This compact design ensures maximum efficiency in the production environment. Furthermore, this machine seamlessly integrates with FCS's Industry 4.0 solution, enabling comprehensive connectivity and smart functionalities.

During the exhibition, FCS will demonstrate the capabilities of the SA-160 model by producing a 45g multi-functional patent storage box with a single mold featuring two openings. Remarkably, this production process achieves a rapid cycle time of just 15 seconds. The SA-160 is equipped with an automatic extraction system and a smart auxiliary detection system. By leveraging process perception technology, it enhances both yield and quality, providing real-time production status updates. With its intelligent monitoring capabilities, the SA-160 significantly reduces the rate of defective products, minimizes manual inspection costs, and mitigates the risk of unexpected shutdowns. This makes it an excellent choice for various industries, including household livelihood, stationery, automotive, and 3C (Computer, Communication, and Consumer Electronics).

With over 50 years of technological advancements and continuous improvement, FCS has established a rich portfolio of products, offering diverse solutions tailored to the unique needs of various industries. As a highlight of the upcoming 2023 Taichung Plastics and Rubber Industry Show, FCS will proudly showcase its most striking innovations, including the "All-electric Multi-component," "Advanced Servo Hydraulic," and "Smart Manufacturing" new models within the plastic industry. By understanding the latest trend, FCS can deliver optimal solutions that perfectly align with customer requirements. In doing so, FCS remains dedicated to its corporate mission of "shaping a better world".

Make sure to visit us at Booth 1048 in the Taichung International Exhibition Center! At the FCS booth, you will have the opportunity to experience firsthand the finest injection molding solutions tailored to our valued customers.

2023 Taichung Plastics and Rubber Industry Show (Jul.13~ Jul.17)

Location:Taichung International Exhibitional Center (No. 19, Section 3, Zhongshan Road, Wuri District, Taichung City 414)

Date:2023 Jul.13~ Jul.17

Booth:1048

》Click for more exhibition info