Intelligent Manufacturing Empowerment: Fuqiangxin New Generation Intelligent Molding System

Since the beginning of the new century, the technologies and cost conditions for realizing intelligent manufacturing have matured. Furthermore, with increasing pressure on resources and the environment, rising labor costs, and other constraints on the manufacturing industry, the intelligent manufacturing market has experienced rapid growth globally in recent years, exhibiting new characteristics. Based on the internet, big data, and intelligent manufacturing equipment, intelligent manufacturing possesses faster and more accurate perception, feedback, and analytical decision-making capabilities, better meeting personalized market demands and enabling flexible product production.

Smart manufacturing makes production processes and supply chain management more efficient, significantly reduces energy consumption, and can also reduce product defect rates through system self-correction. The product cycle from design to market will also be shortened, and faster, more service-oriented products will create more market value for enterprises. All of these factors have led to significant changes in the cost input structure of manufacturing enterprises.

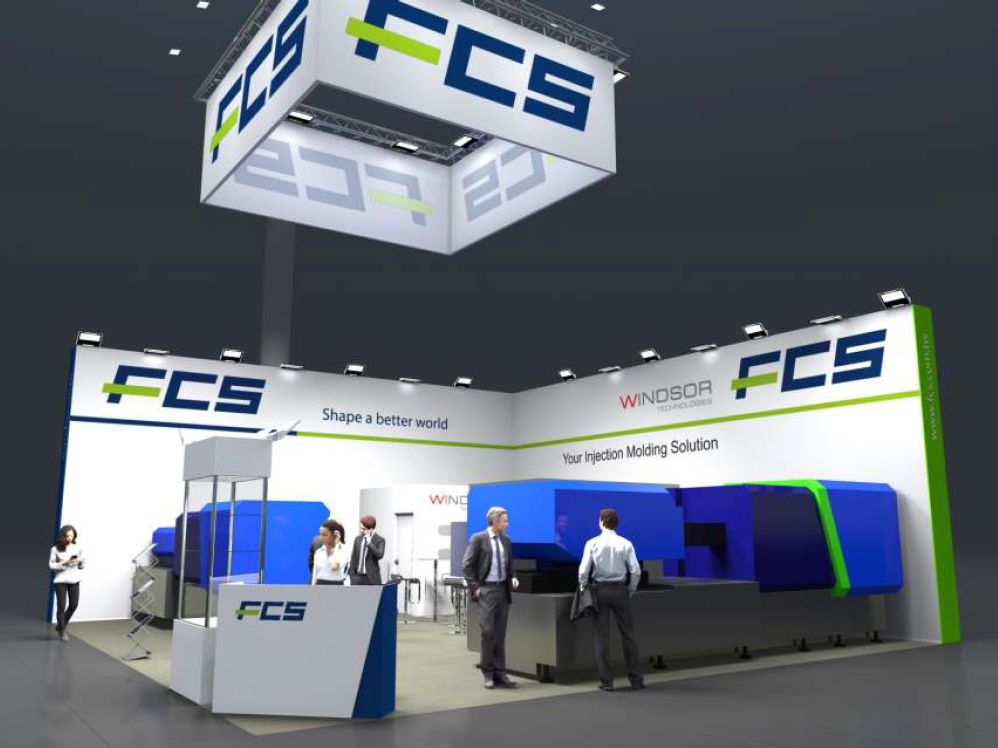

In response to the development trend of energy saving and intelligentization in plastic and rubber equipment, FCS has developed a new generation of intelligent molding system (FA series - a new generation of high-efficiency energy-saving injection molding machine) and in-mold labeling production system (CT series - all-electric injection molding machine) . These products will be showcased at the K Show in Germany in 2019. In addition, in response to the Industry 4.0 trend, FCS will provide intelligent molding solutions. Industry colleagues are welcome to visit our booth for exchange and discussion (Booth: 12 B11).

The FA series is FCS's newly released next-generation high-efficiency and energy-saving injection molding machine. It not only features a comprehensive upgrade in specifications and optimized clamping unit, but also increases the strength of the machine wall structure by 30%. The servo energy-saving oil pump meets the national standard level 1 energy-saving verification, resulting in a significant improvement in injection accuracy and stability. It also boasts an ergonomic and aesthetically pleasing appearance, combining performance, efficiency, and intelligence. Furthermore, it integrates the advantages of a high-end electronic control system and offers optional specifications to meet the customization and high-efficiency needs of various industries.

The CT series is an all-electric injection molding machine that combines an in-mold quality signal monitoring system with high injection speed and long holding pressure. It features a fully servo-driven power drive technology, which is beneficial for producing products with shorter molding cycles, such as thin-walled containers and 3C products, as well as products with long holding pressure, such as optical and thick parts.

With the advent of the global Industry 4.0 era and the trend of transforming plastic and rubber equipment towards energy conservation and intelligence, FCS, with its intelligent injection molding machine controller as the core, collects necessary information from peripheral equipment and process sensors. Through the OPC-UA communication protocol, it uploads process data to the cloud in real time, building a manufacturing resource database. The cloud-based intelligent manufacturing factory system iMF 4.0 (Intelligent ManuFactory 4.0) converts the resource database data into OEE (Overall Equipment Effectiveness) reports, including production trends, work order scheduling, and automatic statistics of production anomalies. This enables Industry 4.0 mobile computing, analysis, and optimization to improve production efficiency and reduce production waste.

The iMF 4.0 smart manufacturing factory system differs from typical remote monitoring systems, going beyond simply monitoring and recording injection molding machine operating parameters (machine parameters). It extends its focus to monitoring and recording molding process parameters (material parameters), enhancing the effectiveness of molding parameter monitoring. Furthermore, it extensively utilizes statistics, variable analysis, and artificial intelligence (AI) to classify and analyze numerical data, improving the real-time nature of anomaly detection and mitigation strategies, significantly increasing the added value of data reuse, simplifying production management, and reducing management labor costs.

Compared to traditional Manufacturing Execution Systems (MES), the iMF 4.0 Smart Manufacturing Factory System is designed for the deployment area planning, effectively integrating Operational Technology (OT), Information Technology (IT), and Communication Technology (CT). OT extracts the production characteristics of the deployment area, while IT and OT connect machine equipment information. The architecture is streamlined and practical, easy to maintain, and relatively inexpensive, making it suitable for management applications of small and medium-sized enterprises. At the same time, it also provides a data exchange interface for large enterprises, allowing for quick connection to their existing MES systems.

Source: https://mp.weixin.qq.com/s/xstHsaAm_7G9TXt61EFN-Q